To determine the centipoise of a fluid it is necessary to multiply the viscosity of the fluid times the specific gravity of the fluid, or measure it directly using an absolute viscometer. The two are related through the specific gravity of the fluid. This is called centistokes, which we have already noted. The other consideration is how the fluid behaves only under the force of gravity. This property is called absolute viscosity (also known as dynamic viscosity) and is measured in centipoises (cP). One is the measure of how the fluid behaves under pressure, such as a pressurized hydraulic line. There are two viewpoints of the resistance to flow that the machine designer is interested in. If the skier was skiing on a lake of SAE 90/ISO 220 gear oil and all of the other conditions were exactly the same, then the amount of spray generated would be considerably less because the fluid would resist the force of the ski to a much greater degree.

Ssu to cst viscosity conversion professional#

We can see how much water a professional skier displaces when he runs through a ski course. Water has a viscosity measured in centistokes of 1.

Think of a water-skier cutting through the water. To simplify, the oil’s viscosity represents the measure for which the oil wants to stay put when pushed (sheared) by moving mechanical components. Viscosity is the measure of the oil’s resistance to flow (shear stress) under certain conditions. You don’t have to listen very long in this field before someone says that viscosity is the most important physical property of a fluid when determining lubrication requirements.

Ssu to cst viscosity conversion iso#

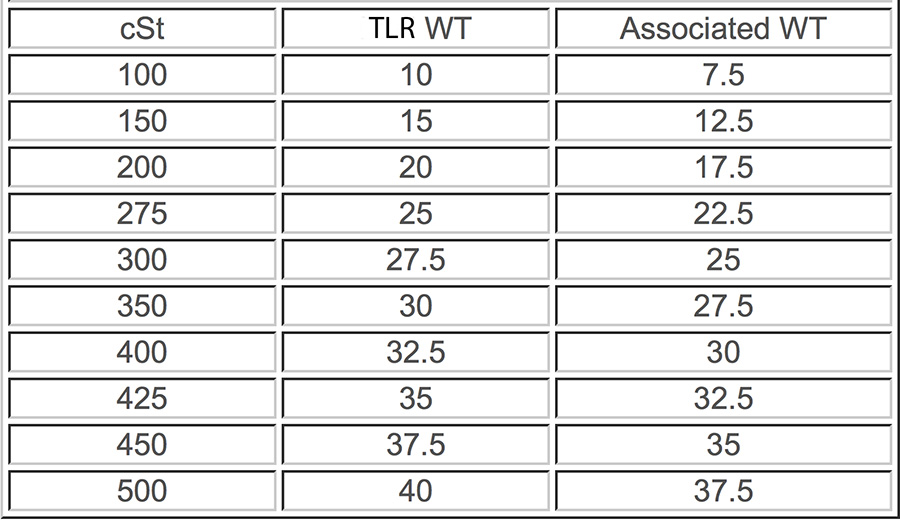

It is known as the International Standards Organization Viscosity Grade, ISO VG for short.

In 1975, the International Standards Organization (ISO), in unison with American Society for Testing and Materials (ASTM), Society for Tribologists and Lubrication Engineers (STLE), British Standards Institute (BSI), and Deutsches Institute for Normung (DIN) settled upon an approach to minimize the confusion. This points to the need for a universally accepted viscosity designation - one that can be used by lubrication practitioners, lubricant suppliers and machinery design engineers simultaneously with minimal confusion. To complicate matters, machinery designers must define the lubricant viscosity in such a way that the equipment user understands clearly what is needed without having to consult outside advice. To the new entrant into the lubrication field, the number of options can be confusing, particularly if the primary lubricant supplier does not associate one of the prominent viscosity systems to the product label. While all of these have served useful purposes to one degree or another, most lubrication practitioners settle on and use one method as a basis for selecting products. To add to the confusion, two measures of temperature (Fahrenheit and Celsius) can be applied to most of these, not to mention that viscosity might be presented at either 40☌ (104☏) or 100☌ (212☏).

There are SAE (Society of Automotive Engineers) grades for gear oils and crankcases (engines), AGMA (American Gear Manufacturers Association) grades for gear oils, SUS (Saybolt Universal Seconds), cSt (kinematic viscosity in centistokes), and absolute viscosity. Through the years, lubricant users have been treated to a number of ways to designate viscosity grades of the lubricants used in manufacturing.

0 kommentar(er)

0 kommentar(er)